New Materials and Processes

Work area

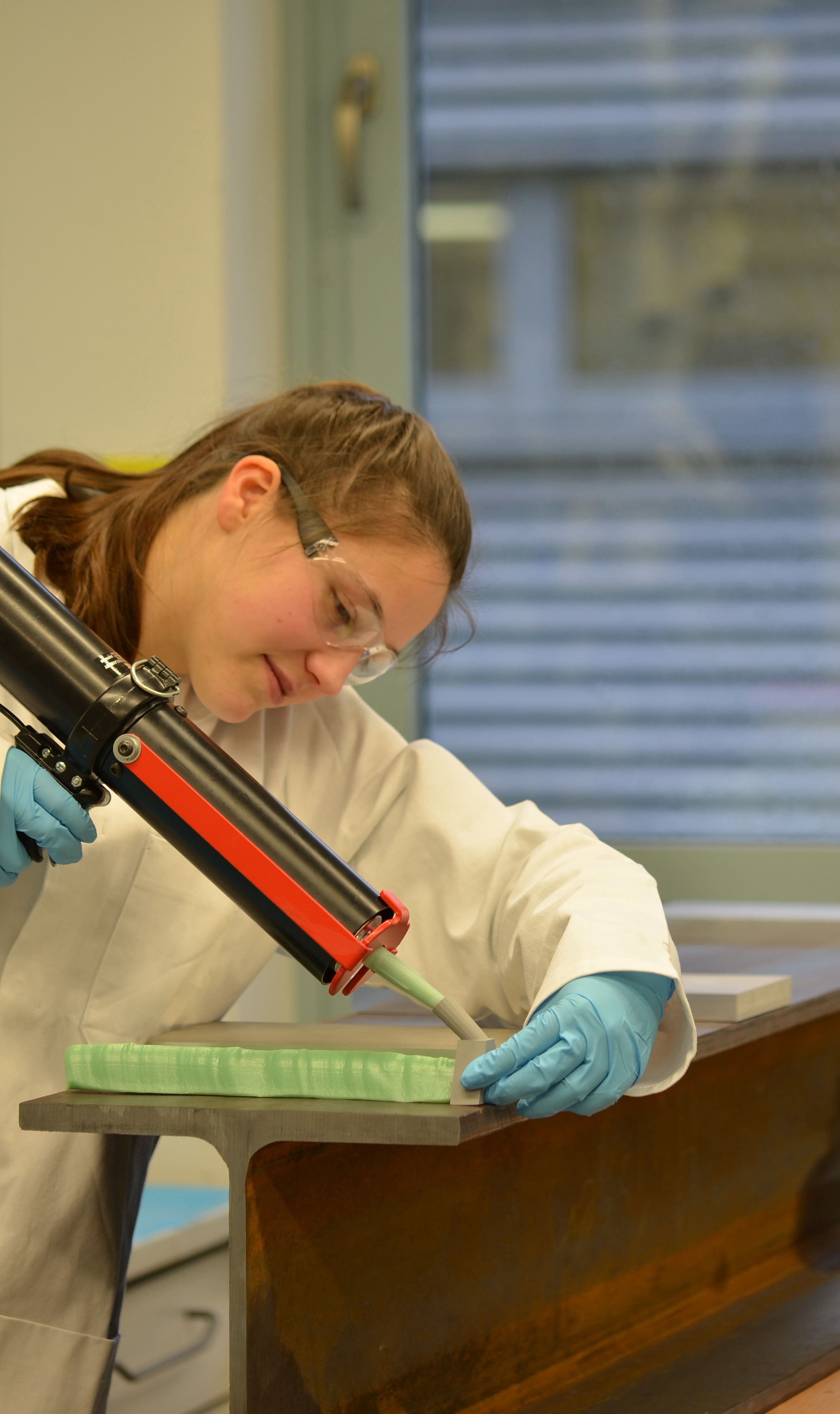

This area of Fraunhofer IGP addresses both current joining issues of lightweight and composite construction and the development and adaption of production methods for fibre composite parts. Further main research focuses are the effects of ageing on materials, adhesive bonded joints and coatings by means of laboratory ageing in an artificial climate.

In cooperation with the accredited test laboratory at the Fraunhofer IGP, materials, joints and coating systems are tested and qualified under standardised conditions. In addition, new testing methods for special applications are developed and employed.

In the field of adhesive bonding technology, the range of services offered by Fraunhofer IGP extend from the bonding-optimised design of parts and assemblies, through the planning and dimensioning of bonded joints right up to the development and qualification of the whole bonding process and the joint.

The focus in the field of fibre composite technology lies on the holistic optimisation of large fibre composite constructions such as the rotor blades of wind turbines, ship superstructures and applications in civil engineering. The work extends from the development of flame-resistant materials through production engineering up to the determination and calculation of indicators.

In the field of corrosion protection and artificial ageing, Fraunhofer IGP’s focus in on the development and qualification of innovative corrosion protection systems with improved properties and the identification of ageing influence.

Since 2020, the individual divisions of the former Adhesive Bonding Technology, Fibre Composite Technology and Corrosion Protection group have formed their own teams. The Adhesive Bonding Technology team is headed by M.Sc. Linda Fröck, while M.Sc. Stefan Schmidt heads up Fibre Composite Technology. Dr-Ing. Michael Irmer leads the Coating, Weathering and Corrosion Protection team. The teams all come under the umbrella of the New Processes and Materials department, which is overseen by Dr-Ing. Nikolai Glück.

Project overview

Adhesive bonding

Bonding as a joining process

Inspection methods for recurrent testing of highly elastic thick-film and structural bonds in shipbuilding applications

As a result of increasing lightweight construction requirements, adhesive technology is becoming more and more important as a joining process in shipbuilding. However, a lack of long-term experience in the maritime sector stands in the way of integrating adhesive technology into production. The aim is to find suitable inspection procedures and intervals for ongoing operations and to expand the experience with adhesive joints in the maritime sector. In order to achieve this, imperfections in adhesive joints typical for shipbuilding are analysed with regard to their damage potential and impact on service life. Based on the data obtained, meaningful inspection intervals are determined for the use of adhesive joints in shipbuilding. In addition, non-destructive

inspection methods (NDT) for use in the shipyard as well as at sea are compiled and checked for applicability.

Fibre composite technology

Enable use in shipbuilding

Non-combustile, fibre-reinforced composite components on cold-curing inorganic matrix systems

In principle, the use of composite materials in shipbuilding is extremely promising due to the great freedom of design, high corrosion resistance and considerable weight savings. However, strict fire protection regulations prevent the use of conventional fibre-reinforced plastic composites (FRP) with organic matrices, which burn with the release of heat in case of fire. The solution to this problem is to substitute the plastics with inorganic, non-combustible matrix systems. Conventional manufacturing processes for FRPs cannot, however, be easily transferred to the inorganic materials.

The AnorKomp project focuses on the optimisation and processing of inorganic systems and processes for the production of corresponding composite components.

corrosion protection

FoKO-Wind

Development of foil coating systems and their application systems and their applications techniques as corrosion protection for offshore wind farms

Offshore Wind Turbines are constantly exposed to wind, water and salt. The protection of the steel structures is guaranteed by high-performance coating systems. The application of these liquid coating materials is associated with enormous effort due to environmental conditions and quality monitoring in the coating process. With the development of a foil coating system, the demands on technical hall equipment can be reduced considerably. For example, there is no need for costly ventilation systems or explosion-proof areas. The development of an automated application system is in the pipeline. In combination with the foil coating system, the need for quality monitoring is significantly reduced. Moreover, fewer employees will be needed to work in hazardous areas.

Project overview

Projects

Services

- Design and qualification of bonding processes and bonded joints through adhesive selection and surface pre-treatment as well as the development of bonding processes

- Development of automation solutions for adhesive technology applications

- Development of composite manufacturing processes and structures

- Design and dimensioning of fibre composite components

- Determination of characteristic values for materials and compounds by static and cyclic tests and polymer analysis

- Analytical and numerical calculation of adhesive joints and fibre composite structures

- Specification and qualification of corrosion protection systems

- Climate simulation and accelerated laboratory ageing for materials, coatings, assemblies and processes

- Bonding process development and component tests under simulated real conditions in a climate chamber

- Development of test methods for combined mechanical and media loads for special application

Equipment

Testing laboratory

- Static universal testing machines (up to 1000 kN)

- Dynamic pulsators (0.1 to 100 kN; 0.1 to 100 Hz)

- Temperature control technology (-170 to 200 °C)

Production technology - Bonding and laminating technology laboratory

- NC workshop for sample preparation and fixture construction

- Atmospheric pressure plasma system and blasting technology

- Vacuum and pump technology for production tests

- Laboratory winding plant

Analytical laboratory - Contact angle measuring device

- DSC device

- Rheometer

- DMA

- Incident and transmitted light microscopes

- Robot-guided ultrasonic testing unit

- Helium leak tester

- Thermography system

Climate laboratory - Corrosion test chambers

- UV irradiation systems

- Climatic cabinets and ovens

- Climate chamber for large-scale tests (90 m³, -50 to 60 °C)

Fraunhofer Institute for Large Structures in Production Engineering IGP

Fraunhofer Institute for Large Structures in Production Engineering IGP